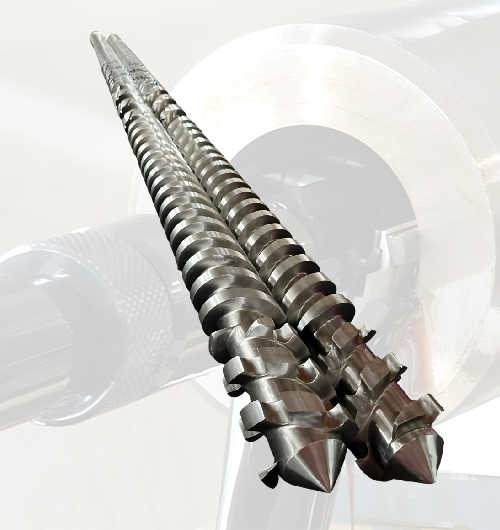

Our parallel twin screw and barrel system is designed and manufactured for high-performance material processing, offering precise control over melting and mixing. With intermeshing parallel screws, the system ensures uniform material transport, providing efficient heat transfer for thorough melting of polymers. The screw design incorporates specific zones for optimal mixing, achieving excellent homogenization while minimizing material degradation. These twin screws can handle high-viscosity materials, with adjustable speeds and torque to accommodate various processing requirements.

We manufacture twin barrel from the premium grade of EN41B ( MUSCO ) with gas Nitrading process, which gives strength and durability to the finish product, for Bimetallic barrel's we use through hardern sleeve of tool steel or D2 material which give longer lifespan as well as wear resistant and corossion resistance

SMEW’s twin screw and barrel system is an ideal solution for industries that require precise and efficient processing of a wide range of materials.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Twin Barrel | Standard | 1.8509 (EN41B) | Gas Nitriding |

- Nitriding Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm |

PVC / HDPE / PP / FRP / uPVC / CPVC | Good | Good |

| Twin Barrel | Standard | 1.8509 (EN41B) | Gas Nitriding + HSS Sleeve |

- Nitriding Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm - HSS Sleeve Hardness: 52 - 55 |

PVC / HDPE / PP / FRP / uPVC / CPVC | Excellent | Good |

| Twin Screw | Standard | 1.8509 (EN41B) | Gas Nitriding |

- Nitriding Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm |

PVC / HDPE / PP / FRP / uPVC / CPVC | Good | Good |

Our Twin Conical Screw and Barrel is manufactured from EN41B (MUSCO) steel which further proceeded with the gas Nitrading process for efficient and controlled processing of materials, especially in extrusion machines applications. The conical geometry of the screws and barrels allows for higher torque transmission, making them ideal for processing materials that require high shear forces. The design ensures excellent material feeding due to the large surface area in the feed zone, gradually compressing the material as it moves toward the barrel's discharge zone.

During the melting process, raw material enters the feed zone, where it is compressed between the two screws. As the material moves through the conical screw flights, frictional heat is generated, which begins to soften and melt the material. Simultaneously, the intermeshing twin screws ensure uniform mixing and homogenization of the molten material, minimizing inconsistencies. The conical profile provides a gradual compression ratio, which improves plasticization and melting efficiency.

This system is highly versatile, suitable for processing a wide range of polymers.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Twin Barrel | Standard | 1.8509 (EN41B) | Gas Nitrading |

- Nitrading Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm |

PVC / HDPE / PP / FRP / uPVC / CPVC | Good | Good |

| Twin Screw | Standard | 1.8509 (EN41B) | Gas Nitrading |

- Nitrading Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm |

PVC / HDPE / PP / FRP / uPVC / CPVC | Good | Good |