SMEW’s Free Flow Ring Plungers are built to improve the flow of materials during the injection molding process. Made from high-quality tool steel, they are strong and durable, capable of withstanding high temperatures and repeated use.

The design of these plungers allows for smooth and easy movement of molten material, helping to prevent blockages or backflow. This ensures that production runs smoothly and quickly, reducing the time needed for each cycle. The plungers also provide a tight seal, stopping any material from leaking, which helps to improve the quality of the final product.

We offer material customization options to fit your specific needs, such as different coatings like - HVOF THERMAL SPRAY , PVD COATING or THROUGH HARDNING for extra protection and various sizes to match your equipment. SMEW’s Free Flow Ring Plungers are a reliable choice for companies looking to make their manufacturing processes faster and more efficient.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Ring Plunger | ---- | 1.8509 (EN41B) | Gas Nitriding | - Nitriding Hardness: 60 - 65 HRC | Generally Low Density Polymer | Good | Good |

| Ring Plunger | ---- | 1.2379 | Through Hardener + Nitriding |

- Hardness: 55 - 60 HRC - Nitriding Hardness: 60 - 65 HRC |

High Density Material | Good | Excellent |

SMEW’s Locking Type Ring Plungers are designed to provide extra security and stability during the injection molding process. These plungers feature a locking mechanism that holds them firmly in place, ensuring smooth and consistent material flow. This design minimizes the chances of slippage or movement, allowing for precise control over the injection process.

Made from durable, high-strength materials like tool steel, these plungers are built to withstand repeated use and high temperatures or with high density material's / High viscosity materials. The locking feature also helps maintain proper alignment, reducing wear and tear on both the plunger and the barrel, which increases the lifespan of the equipment.

Material Customizable options, including various sizes and coatings and surface treatments like gas Nitrading, HVOF THERMAL SPRAY COATING, PVD TIN & CRn Coatings , are available to meet the specific needs of different machinery. Whether you need reliable performance for demanding operations or added precision in molding, SMEW’s Locking Type Ring Plungers deliver consistency and durability.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Ring Plunger | ---- | 1.8509 (EN41B) | Gas Nitriding | - Nitriding Hardness: 60 - 65 HRC | Generally Low Density Polymer | Good | Good |

| Ring Plunger | ---- | 1.2344 (H13) | Through Harding + Gas Nitriding |

- Hardness: 55 - 60 - Nitriding Hardness: 60 - 65 HRC |

High Density Polymers | Excellent | Good |

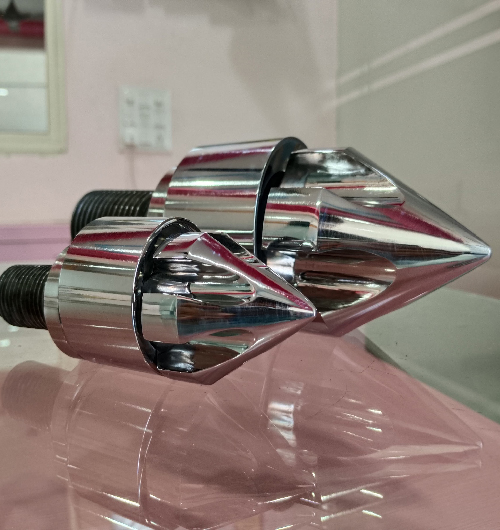

Our High-Speed Mixing Ring Plungers are specifically designed for applications requiring rapid and thorough mixing of materials. The unique helical design at the end of the plunger rings ensures that molten materials are evenly mixed as they flow through the barrel, resulting in a more uniform and high-quality end product.

Built from durable, high-strength materials, these plungers are ideal for high-speed operations and can withstand the intense demands of modern and high density material's for injection molding processes. The enhanced mixing capability helps reduce material inconsistencies and improve production efficiency, making them perfect for use in manufacturing environments that require precision and speed.

Materials Customization options are available to tailor these ring plungers to your specific requirements, whether that involves size adjustments or surface coatings to increase durability. SMEW’s High-Speed Mixing Ring Plungers are an excellent choice for manufacturers seeking to boost mixing efficiency without compromising on product quality.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Ring Plunger | ---- | 1.8509 (EN41-B) | Gas Nitriding | - Nitriding Hardness: 60 - 65 HRC | Generally Low Density Polymers | Good | Good |

| Ring Plunger | ---- | 1.8509 (EN41-B) | Gas Nitriding + Coatings |

- Coating Hardness: 68 - 72 HRC - Nitriding Hardness: 60 - 65 HRC |

30% or More Glass Filled, Talc Filled, Containg Material | Excellent | Good |