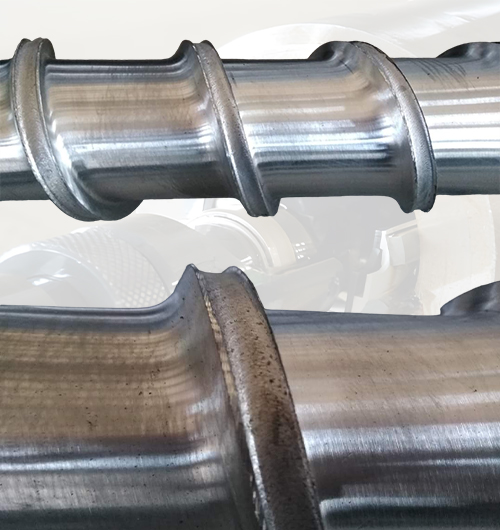

The bimetallic screw is designed for high durability and efficiency in demanding industrial applications, particularly where wear and corrosion are significant concerns. At SMEW, we enhance the screw's performance by incorporating internal grooves on the screw flights or screw channels with a depth of 1 to 2 mm.

To further extend the screw’s life and resistance to abrasive and corrosive materials, we apply a Plasma Transferred Arc (PTA) or tungsten carbide coating to the grooved layer at HRC of 70 ~ 75 . This advanced coating technology offers superior hardness and wear resistance, ensuring that the screw performs reliably even under extreme operating conditions such as high temperatures, pressures, and with materials that contain additive fillers or are chemically corrosive.

The combination of grooved flights and the high-performance coating makes this screw ideal for extrusion and injection molding processes that involve handling challenging materials like 30% or more Glass-Filled polymers, PP + 30% or more Talc filled ,Glass Fibers, Glass Beds, Carbon Fibers or flame-retardant additives. SMEW’s bimetallic screws not only reduce maintenance costs but also enhance productivity by minimizing downtime and extending the operational life of the machinery.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Screw | 18 mm to 150 mm (Length Upto 5 m) | 1.8509 (EN41B) | Gas Nitrading + Hard Chrome |

- Nitriding Hardness: 60 - 65 HRC - Nitriding Layer Depth: 0.4 - 0.6mm - Hard Chrome Hardness: 68- 72 HRC |

Transparent Materials, PC, PMMA, PP | Good | Good |

| Screw | 18 mm to 150 mm (Length Upto 5 m) | 1.8509 or 1.2344 (EN41B or Tool Steel H13) | Coating On Screw Flight: Tungsten Carbide Material Nickel Based Alloy |

- Nitriding Hardness: 60 - 65 HRC - Layer Depth: 0.4 - 0.6mm - Coating Hardness: 70 - 75 HRC |

≤ 45% Glass Fiber or Talc Filled, PE, PP, ABS, AS, PS, PA, PC, PPS | Excellent | Excellent |

| Screw | 18 mm to 150 mm (Length Upto 5 m) | 1.8509 or 1.2344 (EN41B or Tool Steel H13) | Coating On Screw Flight: Tungsten Carbide Cobalt Based Alloy | - Coating Hardness: 72 - 78 HRC | ≤ 65% Glass Fiber or Talc Filled, PE, PP, ABS, AS, PS, PA, PC, PPS | Premium | Excellent |

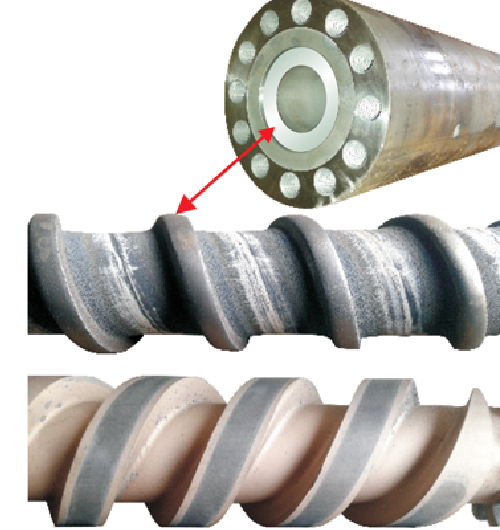

The bimetallic barrel at SMEW is expertly engineered to deliver exceptional durability and performance in demanding processing environments. We start with high-quality EN41B steel from Musco, known for its excellent toughness and hardness. To enhance the barrel's wear resistance, we employ a gas nitriding process, which hardens the surface to a depth of 0.5 to 0.6 mm. This treatment significantly improves the barrel's resistance to abrasion and corrosion.

Following nitriding, the barrel undergoes precision grinding and internal honing to achieve exacting tolerances and a smooth finish but During machining, we carefully enlarge the internal diameter by a few millimeters to ensure optimal fit and functionality of sleeve. To further augment the barrel's durability, we add a sleeve made from high-grade tool steel or die steel material our sleeves are through harden which providies an additional layer of protection and wear resistance.

In future we are also focusing in spin cast tungsten carbide process which gives inlay coating of tungsten carbide. This combination of high-strength materials and advanced processing techniques ensures that SMEW's bimetallic barrels deliver reliable performance, reduced maintenance needs, and extended service life, even under the most challenging conditions. They are ideal for use in extrusion and injection molding applications that require robust, long-lasting components.

| Product | Diameter Range | Material Name/No. | Process | Technical Parameter | Material Type | Wear Resistance Ability | Corrosion Resistance Ability |

|---|---|---|---|---|---|---|---|

| BARREL | 18 mm to 150 mm | 40Cr | Inlay Bimetallic Coating Process ( 5% carbide particles) | Fe + Ni Based Coating Process Coating Hardness - 58 to 62 HRC |

Used for virgin polymers & < 35% Glass Filled, Flame Radent containing polymers | Moderate | Moderate |

| BARREL | 18 mm to 150 mm | 40CrMo | Inlay Bimetallic Coating Process ( 30% carbide particles ) | Ni + W + Cr Based Coating Process Coating Hardness - 61 to 63 HRC | Used up to < 50% Glass Filled, Halogen Free Polymers, Carbon Fibers, Mineral Fibers, Metal powder | Excellent | Superior |

| BARREL | 18 mm to 150 mm | 1.8509 (EN41-B) | Inlay Bimetallic Coating Process ( 50 to 60% carbide particles ) | Co + W + Cr + V Based Coating Process Coating Hardness - 62 to 70 HRC | OPTICAL GRADE PC, PEEK, Used up to 60% or more Glass Filled,Flame Radent, Talc Filled Polymers | Premium | Premium |

SMEW's bimetallic torpedo and ring plungers are engineered to meet the stringent demands of injection molding and extrusion processes. These components are essential for precise control and efficient flow of molten materials through molding or extrusion systems.

Constructed with a robust core material such as die steel or EN41B steel, coupled with HVOF thermal spray of tungsten carbide, these plungers feature a bimetallic layer that combines high-strength steel with a wear-resistant alloy. This construction enhances the plungers' durability, offering superior resistance to wear and corrosion.

The bimetallic layer not only extends the plunger's lifespan but also ensures consistent performance under high pressure and temperature conditions. SMEW stands behind the quality of our bimetallic plungers with a warranty of 1.5 to 2 years, even when processing materials with 30% or more additives and fillers.

| Product | Diameter Range | Material Name/No. | Process | Technicle Perameter | Material Type | Wear Resistance Ability | Corossion Resistance Ability |

| Ring Plunger | ---- | 1.2379 (D2) | Through Hardness | - Hardness: 55 - 60 HRC | Material Containg Glass Filled, Glass Fiber, Fiber reinforced Can be Use | Good | Excellent |

| Ring Plunger | ---- | 1.2344 (H13) | Through Hardness | - Hardness: 55 - 60 HRC | Material Containg Glass Filled, Glass Fiber, Fiber reinforced Can be Use | Excellent | Good |

| Ring Plunger | ---- | Select (H13 or D2) | Through Hardness + TCC Coating |

- Coating Layer: 0.3mm - Hardness: 70 - 75 HRC |

45% or More Additives or Fillers | Premium | Premium |